Selective Laser Sintering

For Concept Models, Rapid Prototyping, Master Patterns and Low Volume Manufacturing Get A QuoteGet Fast Answers and Results

You can depend on us for…

- SAME DAY PRICING – We are standing by to review your product and let you know exactly what its going to cost

- LIVE ENGINEERING SUPPORT – We are standing by to answer any of your questions so you can make the best decision and move your project along quickly.

- FAST DELIVERY – Recieve your parts within 24 to 48 hours anywhere in the United States (*Same day delivery in the Twin Cities Metro Area)

Partner With Pros

Leverage an experienced engineering team that you can trust to manage everything from a small one-off part to high and low volume manufacturing to overall project management.

You Design It

Send us your CAD file and our staff helps identify the best process and material for your project.

We Make It

We use one of our industrial grade 3D Printers to create your parts. We leverage the following technologies: Stereolithography (SLA), Fused Deposition Modeling (FDM), and Selective Laser Sintering (SLS)

You Get It

When your parts are complete we package them up and rush them to you.

Don't Know if 3D Printing is the Right Option for Your Parts?

Try Our Interactive Design Verification Today

Choosing the right material for your project is critical. DuraForm PA (Nylon 12) offers a versatile approach to designs with high complexity. Another benefit to DuraForm PA is the lack of support structures needed, meaning you get a good surface finish straight out of the machine.

DuraForm PA (Nylon 12) SLS

PA 650 allows for low to mid-volume rapid prototyping and manufacturing, achieving thin walls and excellent detail and feature resolution.

- Strength

- Surface Finish

- Cost

Selective Laser Sintering works by heating up a vat of material close to its melting point. Once it is heated up a laser is directed down to fuse the material together to build your parts.

3D Systems SPro 60

Selective Laser Sintering (SLS)

Description:

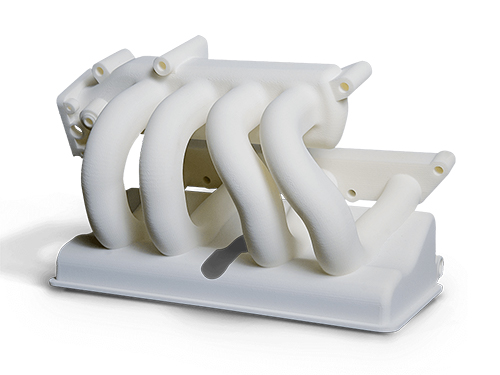

SLS involves the use of a high power laser to fuse small particles of nylon powder into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part on the surface of a powder bed.

Applications:

- Engine housings and other protective covers

- Jigs and fixtures

- Machinery components

- Lightweight duct work

- Small to medium run manufacturing

Build Size:

13 x 11 x 16 inches (330 x 280 x 406 mm)

Precision:

+/- 0.005” or +/- 0.002” per inch, whichever is greater

Available Materials:

Have A Cad File?

Upload your file. We’ll take a look and get back to you ASAP.

What Past Clients Are Saying…

“3DPA is outstanding at delivering detailed, quick-turn 3D printed parts. They offer some of the fastest lead times, at a very competitive price!”

“They did some prototypes for my business. Quoted quickly, price was fair, and the parts were done in a couple days. Great company to work with, and I’m sure we will be back!”