Processes

The right process to complete your products begin with 3D Printing Ally…

Stratasys Fortus 400mc

Fused Deposition Modeling (FDM)

Description:

FDM builds three-dimensional parts by melting and advancing a fine ribbon of plastic through a computer-controlled extrusion head, producing parts that are ready to use.

Applications:

- Low-volume production of complex end-use parts

- Prototypes for form, fit and function testing

- Prototypes directly constructed in production materials

Build Size:

14 x 16 x 16 inches (406 x 355 x 406 mm)

Precision:

+/- 0.005” or +/- 0.0015” per inch, whichever is greater

Available Materials:

3D Systems SPro 60

Selective Laser Sintering (SLS)

Description:

SLS involves the use of a high power laser to fuse small particles of nylon powder into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part on the surface of a powder bed.

Applications:

- Engine housings and other protective covers

- Jigs and fixtures

- Machinery components

- Lightweight duct work

- Small to medium run manufacturing

Build Size:

13 x 11 x 16 inches (330 x 280 x 406 mm)

Precision:

+/- 0.005” or +/- 0.002” per inch, whichever is greater

Available Materials:

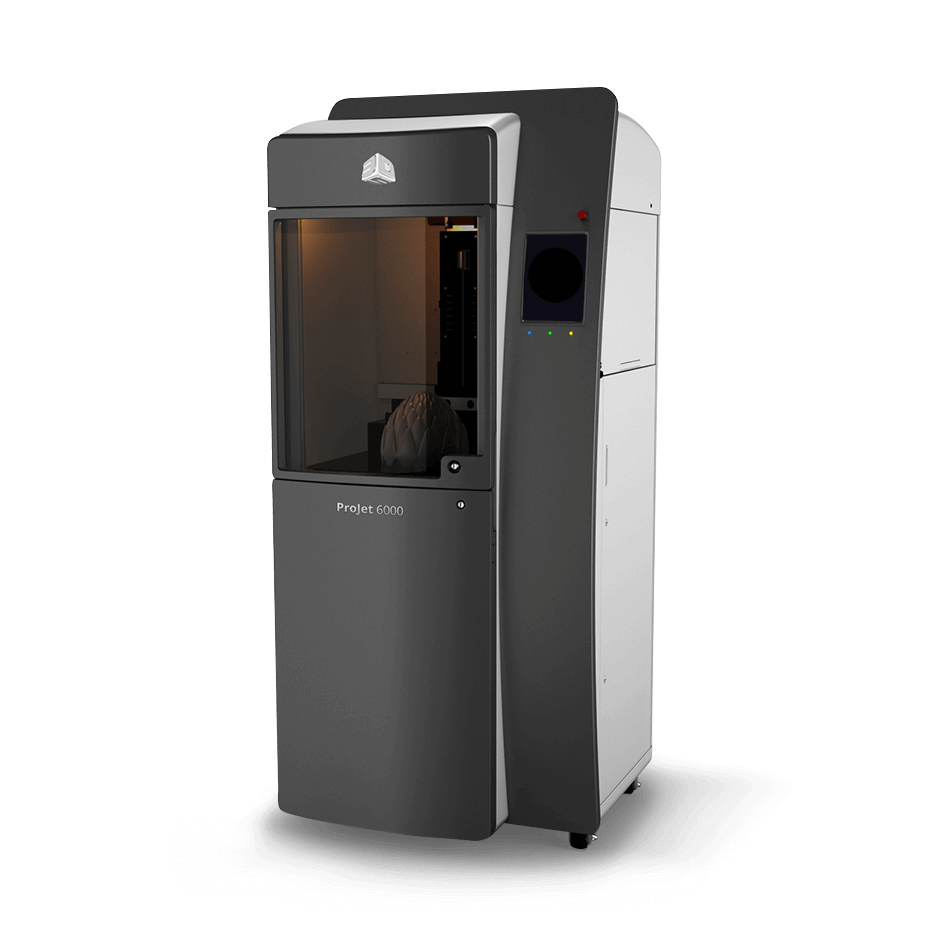

3D Systems ProJet 6000 HD

Stereolithography (SLA)

Description:

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin.

Applications:

- Design verification

- Complex assemblies

- Mass customization of product (orthodontic, dental)

- Assembly jigs and fixtures

Build Size:

10 x 10 x 10 inches (250 x 250 x 250 mm)

Precision:

+/- 0.004” or +/- 0.001” per inch, whichever is greater

Available Materials:

3D Systems ProJet 7000 SD

Stereolithography (SLA)

Description:

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. Same perks and process as the Projet 6000 but with a larger build size.

Applications:

- Design verification

- Complex assemblies

- Mass customization of product (orthodontic, dental)

- Assembly jigs and fixtures

Build Size:

15 x 15 x 10 inches (380 x 380 x 250 mm)

Precision:

+/- 0.004” or +/- 0.001” per inch, whichever is greater

Available Materials: